As an independent service provider (ISP) to the wind energy industry that recently surpassed 10,000 wind turbine component repairs, PSI Repair Services has earned the confidence of some of the largest wind farms in the United States. So, when we were recently approached with the question, “What advice would you give to wind farm owners when it comes to selecting an ISP?,” two points came to mind: First, PSI recommends an ISP that works closely with wind farm operations and maintenance (O&M) staff to uncover repair and reliability solutions. Second, PSI recommends an ISP with the right tools and talent in place to solve your problems and reduce operating costs.

At PSI, we understand that wind turbine component failures typically involve multiple factors. That’s why we work closely with O&M staff to learn about nagging performance issues. Our experienced engineers have a track record of putting an end to nagging performance issues by engineering more efficient solutions that increase mean time between failures (MTBFs) and reduce operating costs. For example, when our engineers noticed a high volume of H-bridge/hub converter failures, they studied the design and developed a replacement switching board that lasts 2-3 times longer. Today, every H-bridge/hub converter repair uses PSI’s upgraded design to help wind farms increase MTBFs and reduce operating costs.

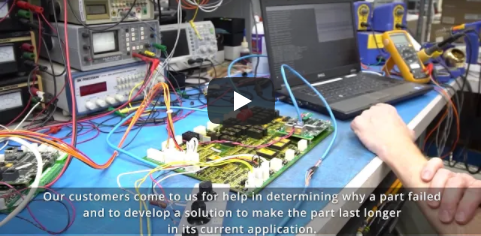

PSI also uses state-of-the-art diagnostic equipment to ensure wind farms receive the very best repair quality. By combining powerful tools and engineering experience, PSI can identify why components fail and recommend corrective actions to resolve the issue the first time around, avoiding the frustrating time and costs associated with repeat failures.

All in all, PSI believes in making life easier for wind farm owners. And shouldn’t that be the goal for hiring an ISP in the first place?